Table of Contents

PT All Lifting Indonesia offers expert wire rope greasing services utilizing advanced wire rope lubricators and modern automatic greasing systems. Our maintenance solutions ensure effective lubrication for optimal performance and extended wire rope life.

Why Wire Rope Lubrication Matters in the Lifting & Rigging Industry

At PT All Lifting Indonesia, we understand that proper wire rope lubrication is essential to maintaining the safety, performance, and longevity of your lifting equipment. Wire ropes on cranes, hoists, and other heavy-duty machinery are exposed to constant movement, heavy loads, and harsh environments—making them highly vulnerable to wear, corrosion, and internal friction.

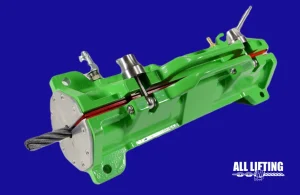

Our greasing services ensure that every strand of your wire rope is protected using high-quality lubricants and the latest greasing technology, including automatic wire rope lubricators like the Viper MKII. This not only helps maintain flexibility and reduce downtime, but also significantly extends the service life of your equipment.

Whether you need manual or automatic greasing solutions, we’ve got you covered. Trust us to deliver reliable wire rope maintenance that keeps your operations running smoothly and safely.

The Role of Wire Rope Greasing in the Lifting & Rigging Industry

In the world of lifting and rigging, wire rope lubrication is a critical part of routine maintenance that should never be overlooked. Applying the right wire rope grease offers multiple performance and longevity benefits for your equipment:

- Reduces Friction

Proper lubrication minimizes friction between rope strands and other components, preventing excessive wear and keeping the wire rope in top condition during operation. - Boosts Efficiency & Performance

Well-lubricated ropes move more smoothly and efficiently—essential for lifting systems where smooth operation directly impacts safety and productivity. - Protects Against Rust & Corrosion

Wire rope grease forms a protective barrier against moisture, steam, and aggressive chemicals, helping to prevent rust and corrosion that could weaken the rope structure. - Extends Wire Rope Lifespan

By reducing wear and shielding against corrosion, regular greasing significantly extends the service life of your wire ropes and lifting equipment. - Cuts Maintenance Costs

Investing in high-quality wire rope grease pays off long-term. Well-maintained equipment is more durable, experiences fewer breakdowns, and reduces costly repairs or replacements.

ADVANTAGES OF AUTOMATIC GREASING MACHINES (WIRE ROPE GREASE LUBRICATORS) VS. MANUAL GREASING

At PT All Lifting Indonesia, we use advanced automatic wire rope greasing machines (Wire Rope Grease Lubricators) that offer significant advantages over traditional manual greasing methods—especially in terms of time efficiency, consistency, and minimizing human error.

Here’s a comparison between automatic and manual wire rope lubrication methods:

1. TIME & RESOURCE EFFICIENCY

✅ Automatic & Centralized Greasing:

Delivers even and timely lubrication to multiple points simultaneously—without manual intervention. It’s faster, more efficient, and reduces labor needs.

❌ Manual Greasing:

Requires point-by-point lubrication, which is time-consuming and labor-intensive, and increases the risk of uneven greasing due to human error.

2. CONSISTENT LUBRICATION

✅ Automatic & Centralized Greasing:

Ensures accurate, even, and consistent application of wire rope grease, preventing over- or under-lubrication that could damage components.

❌ Manual Greasing:

Relies on operator skill; grease quantity may vary, risking improper lubrication and leading to premature wear or failure.

3. COST SAVINGS

✅ Automatic & Centralized Greasing:

Provides long-term savings through reduced labor, efficient lubricant use, and extended equipment lifespan. We offer sales, rental, and full-service solutions for wire rope grease lubricators.

❌ Manual Greasing:

Lower upfront cost, but often more expensive in the long run due to wasted grease, longer downtime, and increased maintenance costs.

4. SAFETY & MINIMIZING HUMAN ERROR

✅ Automatic & Centralized Greasing:

Delivers consistent lubrication even in hard-to-reach areas, reducing operator error, equipment damage, and accident risks.

❌ Manual Greasing:

Highly dependent on the operator, prone to error, and can compromise equipment safety and reliability.

WIRE ROPE GREASING MACHINE RENTAL SERVICE – PT ALL LIFTING INDONESIA

PT All Lifting Indonesia offers professional wire rope greasing machine rental services complete with experienced operators. Using the latest wire rope grease lubricator technology and skilled technicians, we ensure each lubrication point is treated thoroughly and effectively.

💡 “We provide efficient and effective wire rope lubrication solutions.”

Our wire rope greasing machine rental service offers a hassle-free solution for your operations—no need for costly equipment investment or in-house training. This means lower maintenance costs for your wire ropes while maintaining optimal performance.

Trust PT All Lifting Indonesia to handle your wire rope lubrication needs with precision, safety, and cost-efficiency. Experience better equipment care and maximize your operational uptime—without the overhead.

Ready to optimize your wire rope maintenance?

Choose our automatic greasing solutions for safer, faster, and more efficient operations. Contact us for sales, rental, or professional wire rope greasing services with the Viper MKII Lubricator!

Email: julia@alllifting.co.id

Phone: +62811 931 719